W

WA machine is any physical system with ordered structural and functional properties. It may represent human-made or naturally occurring device molecular machine that uses power to apply forces and control movement to perform an action. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems.

W

WAir bearings are fluid bearings that use a thin film of pressurized gas to provide a low friction load-bearing interface between surfaces. The two surfaces do not touch, thus avoiding the traditional bearing-related problems of friction, wear, particulates, and lubricant handling, and offer distinct advantages in precision positioning, such as lacking backlash and static friction, as well as in high-speed applications. Space craft simulators now most often use air bearings and 3-D printers are now used to make air-bearing-based attitude simulators for CubeSat satellites.

W

WAn anaesthetic machine or anesthesia machine is a medical device used to generate and mix a fresh gas flow of medical gases and inhalational anaesthetic agents for the purpose of inducing and maintaining anaesthesia.

W

WAn autopen or signing machine is a device used for the automatic signing of a signature or autograph. Many celebrities, politicians and public figures receive hundreds of letters a day, many of which request a personal reply; this leads to a situation in which either the individual must artificially reproduce their signature or heavily limit the number of recipients who receive a personal response. Given the exact verisimilitude to the real hand signature, the use of the autopen allows for a small degree of wishful thinking and plausible deniability as to whether a famous autograph is real or reproduced, thus increasing the perception of the personal value of the signature by the lay recipient. However, known or suspected autopen signatures are also vastly less valuable as philographic collectibles; legitimate hand-signed documents from individuals known to also use an autopen usually require verification and provenance to be considered valid.

W

WA block and tackle or only tackle is a system of two or more pulleys with a rope or cable threaded between them, usually used to lift heavy loads.

W

WThe Demaco extruder is a pasta extruder built by Demaco in West Melbourne, Florida, United States. It is the first pasta extruder ever built for USDA sanitary food plants. Its design allowed food producers to use an extruder directly in fresh, frozen and canning factories.

W

WIn mathematics, the dual quaternions are an 8-dimensional real algebra isomorphic to the tensor product of the quaternions and the dual numbers. Thus, they may be constructed in the same way as the quaternions, except using dual numbers instead of real numbers as coefficients. A dual quaternion can be represented in the form A + εB, where A and B are ordinary quaternions and ε is the dual unit, which satisfies ε2 = 0 and commutes with every element of the algebra. Unlike quaternions, the dual quaternions do not form a division algebra.

W

WThe elastic and inelastic collisions apparatus is a large apparatus to study elastic and inelastic collisions.

W

WThe Euphonia was a talking machine created in the early to mid-nineteenth century by the Austrian inventor Joseph Faber and exhibited in 1845 in Philadelphia and in 1846 in London's Egyptian Hall. An earlier version of the invention had been destroyed in 1844 by Faber.

W

WA four-slide, also known as a multislide, multi-slide, or four-way, is a metalworking machine tool used in the high-volume manufacture of small stamped components from bar or wire stock. The press is most simply described as a horizontal stamping press that uses cams to control tools. The machine is used for progressive or transfer stamping operations.

W

WA glazing jack or glazing machine is a type of machine used for polishing leather. The machine consists of a solid glass cylinder, typically around two inches (5 cm) in diameter and six inches (15 cm) in length, mounted to the end of a rotating or reciprocating arm. The arm repeatedly and rapidly draws the glass across the surface of the leather, with significant downward pressure, as the operator moves the leather underneath the arm.

W

WThe Gunderson Do-All Machine is a colorful, interconnected network of dozens of machines that have been cross-sectioned to reveal their internal operating mechanisms. It was designed by Mark Gunderson to illustrate mechanical concepts.

W

WLifting equipment, also known as lifting gear, is a general term for any equipment that can be used to lift and lower loads. Types of lifting equipment includes heavy machinery such as the patient lift, overhead cranes, forklifts, building cradles, passenger lifts, and can also include smaller accessories such as chains, hooks, and rope. Generally, this equipment is used to move material that cannot be moved with manual labor, and are tools used in most work environments, such as warehouses, and is a requirement for most construction projects, such as bridges and buildings. This equipment can also be used to equip a larger number of packages and goods, requiring less persons to move material. Lifting equipment includes any form of equipment that is used for vertical lifting, and equipment used to move material horizontally is not considered lifting equipment, nor is equipment designed to support. As lifting equipment can be dangerous to use, it is a common subject of safety regulations in most countries, and heavy machinery usually requires certified workers to limit workplace injury.

W

WA loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

W

WThe Machine Age is an era that includes the early-to-mid 20th century, sometimes also including the late 19th century. An approximate dating would be about 1880 to 1945. Considered to be at its peak in the time between the first and second world wars, the Machine Age overlaps with the late part of the Second Industrial Revolution and continues beyond it until 1945 at the end of World War II. The 1940s saw the beginning of the Atomic Age, where modern physics saw new applications such as the atomic bomb, the first computers, and the transistor. The Digital Revolution ended the intellectual model of the machine age founded in the mechanical and heralding a new more complex model of high technology. The digital era has been called the Second Machine Age, with its increased focus on machines that do mental tasks.

W

WMachine element or hardware refers to an elementary component of a machine. These elements consist of three basic types:structural components such as frame members, bearings, axles, splines, fasteners, seals, and lubricants, mechanisms that control movement in various ways such as gear trains, belt or chain drives, linkages, cam and follower systems, including brakes and clutches, and control components such as buttons, switches, indicators, sensors, actuators and computer controllers.

W

WIn engineering, a mechanism is a device that transforms input forces and movement into a desired set of output forces and movement. Mechanisms generally consist of moving components which may include:Gears and gear trains; Belts and chain drives; Cams and followers; Linkages; Friction devices, such as brakes or clutches; Structural components such as a frame, fasteners, bearings, springs, or lubricants; Various machine elements, such as splines, pins, or keys.

W

WThe machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

W

WA machine shop is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plastic. A machine shop can be a small business or a portion of a factory, whether a toolroom or a production area for manufacturing. The building construction and the layout of the place and equipment vary, and are specific to the shop; for instance, the flooring in one shop may be concrete, or even compacted dirt, and another shop may have asphalt floors. A shop may be air-conditioned or not; but in other shops it may be necessary to maintain a controlled climate. Each shop has its own tools and machinery which differ from other shops in quantity, capability and focus of expertise.

W

WA machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

W

WThe mechanical paradox is an apparatus for studying physical paradoxes. It consists of a trapezoidal veneered wooden frame with two brass rails, and a pair of brass cones joined at their bases by a wooden disk which rests on the rails. When the double cone is placed at the low end of the frame, it automatically starts to roll upward, giving the impression of escaping the universal law of the gravitational force.

W

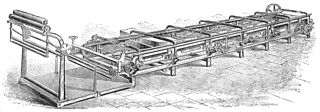

WA paper machine is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web.

W

WA paper-ruling machine is a device for ruling paper. In 1770, John Tetlow was awarded a patent for a "machine for ruling paper for music and other purposes." William Orville Hickok invented an "improved ruling machine" in the mid-19th century. As the device is designed for drawing lines on paper, it can produce tables and ruled paper.

W

WThe Photostat machine, or Photostat, was an early projection photocopier created in the decade of the 1900s by the Commercial Camera Company, which became the Photostat Corporation. The "Photostat" name, which was originally a trademark of the company, became genericized, and was often used to refer to similar machines produced by the Rectigraph Company.

W

WA record press is a machine for manufacturing vinyl records. It is essentially a hydraulic press fitted with thin nickel stampers which are negative impressions of a master disc. Labels and a pre-heated vinyl patty are placed in a heated mold cavity. Two stampers are used, one for each of side of the disc. The record press closes under a pressure of about 150 tons. The process of compression molding forces the hot vinyl to fill the grooves in the stampers, and take the form of the finished record.

W

WA roof seamer is a portable roll forming machine that is used to install mechanically seamed structural standing seam metal roof panels, as part of an overall metal construction building envelope system. The machine is small and portable to be handled by an operator on top of a roof. The machine is applied to the overlapping area when two parallel roof panels meet. The action of the machine bends the two panels together to form a joint that has weather-tight qualities superior to other types of roof systems and cladding.

W

WA rotary transfer machine is a machine tool, typically for metal working by machining, comprising a large indexing table with machining stations surrounding the table. Such rotary transfer machines are used for producing a large number of parts in fairly short cycle times.

W

WA rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage and a rotating part to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants. A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union, rotorseal, rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union

W

WA screw axis is a line that is simultaneously the axis of rotation and the line along which translation of a body occurs. Chasles' theorem shows that each Euclidean displacement in three-dimensional space has a screw axis, and the displacement can be decomposed into a rotation about and a slide along this screw axis.

W

WA self-propelled modular transporter or sometimes self-propelled modular trailer (SPMT) is a platform vehicle with a large array of wheels. SPMTs are used for transporting massive objects such as large bridge sections, oil refining equipment, cranes, motors, spacecraft and other objects that are too big or heavy for trucks. Trucks can however provide traction and braking for the SPMTs on inclines and descents.

W

WA self-replicating machine is a type of autonomous robot that is capable of reproducing itself autonomously using raw materials found in the environment, thus exhibiting self-replication in a way analogous to that found in nature. The concept of self-replicating machines has been advanced and examined by Homer Jacobson, Edward F. Moore, Freeman Dyson, John von Neumann and in more recent times by K. Eric Drexler in his book on nanotechnology, Engines of Creation and by Robert Freitas and Ralph Merkle in their review Kinematic Self-Replicating Machines which provided the first comprehensive analysis of the entire replicator design space. The future development of such technology is an integral part of several plans involving the mining of moons and asteroid belts for ore and other materials, the creation of lunar factories, and even the construction of solar power satellites in space. The von Neumann probe is one theoretical example of such a machine. Von Neumann also worked on what he called the universal constructor, a self-replicating machine that would be able to evolve and which he formalized in a cellular automata environment. Notably, Von Neumann's Self-Reproducing Automata scheme posited that open-ended evolution requires inherited information to be copied and passed to offspring separately from the self-replicating machine, an insight that preceded the discovery of the structure of the DNA molecule by Watson and Crick and how it is separately translated and replicated in the cell.

W

WA Z-Mill or Sendzimir Mill is a machine for rolling steel. Unlike a traditional rolling mill this 20-high cluster mill configuration utilizes cascaded supporting rolls to apply force on the small work rolls in the center. This allows the application of a higher roll pressure without bending the work rolls, which would result in poor metal quality. Thus very hard and elastic materials can be rolled.

W

WA Stenter is a specialist oven used in the textile industry for drying and heat treating fabric after wet processing.

W

WA strand jack is a jack used to lift very heavy loads for construction and engineering purposes. Strandjacking was invented by VSL Australia's Patrick Kilkeary & Bruce Ramsay in 1969 for concrete post tensioning systems, and is now widely used for heavy lifting, to erect bridges, offshore structures, refineries, power stations, major buildings and other structures where the use of conventional cranes is either impractical or too expensive.

W

WA tablet press is a mechanical device that compresses powder into tablets of uniform size and weight. A tablet press can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, nutraceuticals, cleaning products, industrial pellets and cosmetics. To form a tablet, the granulated powder material must be metered into a cavity formed by two punches and a die, and then the punches must be pressed together with great force to fuse the material together.

W

WA tortilla machine, called in Spanish máquina tortilladora, is a machine for processing corn dough (masa) into corn tortillas for serial production. They are usually found in tortillerías or tortilla shops in Mexico and some parts of the United States and produce from 30 to 60 tortillas per minute.

W

WA tunnel washer, also called a continuous batch washer, is an industrial washing machine designed specifically to handle heavy loads of laundry.

W

WA useless machine or useless box is a device which has a function but its direct purpose is deliberately unknown.

W

WA winding machine or winder is a machine for wrapping string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.