W

WA reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

W

WIn a piston engine, the main bearings are the bearings which hold the crankshaft in place and allow it to rotate within the engine block.

W

WIn a piston engine, the main bearings are the bearings which hold the crankshaft in place and allow it to rotate within the engine block.

W

WApplications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the "working fluid", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction.

W

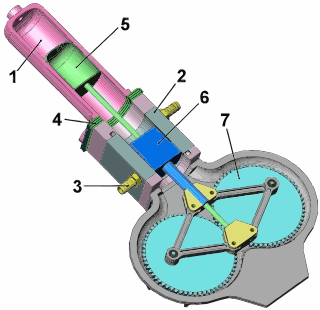

WAxial engines are a type of reciprocating engine with pistons arranged around an output shaft with their axes parallel to the shaft. Barrel refers to the cylindrical shape of the cylinder group whilst the Z-crank alludes to the shape of the crankshaft.

W

WThe Bourke engine was an attempt by Russell Bourke, in the 1920s, to improve the two-stroke engine. Despite finishing his design and building several working engines, the onset of World War II, lack of test results, and the poor health of his wife compounded to prevent his engine from ever coming successfully to market. The main claimed virtues of the design are that it has only two moving parts, is lightweight, has two power pulses per revolution, and does not need oil mixed into the fuel.

W

WThe compression ratio is the ratio between the volume of the cylinder and combustion chamber in an internal combustion engine at their maximum and minimum values.

W

WA crankshaft is a shaft driven by a crank mechanism, consisting of a series of cranks and crankpins to which the connecting rods of an engine is attached. It is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion, whereas in a reciprocating compressor, it converts the rotational motion into reciprocating motion. In order to do the conversion between two motions, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

W

WThe Elsbett engine is an 89 HP, direct-injection diesel engine designed to run on straight vegetable oil. The engine is also known as Elko engine and was invented by Ludwig Elsbett.

W

WThe Ericsson cycle is named after inventor John Ericsson who designed and built many unique heat engines based on various thermodynamic cycles. He is credited with inventing two unique heat engine cycles and developing practical engines based on these cycles. His first cycle is now known as the closed Brayton cycle, while his second cycle is what is now called the Ericsson cycle. Ericsson is one of the few who built open-cycle engines, but he also built closed-cycle ones.

W

WA flathead engine, also known as a sidevalve engine or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine.

W

WFlathead motorcycles are a type of bike that was a standard for pre-war motorcycles, in particular US V-twins such as Harley-Davidson and Indian, some British singles, BMW flat twins and Russian copies thereof.

W

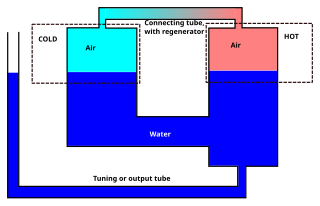

WA Fluidyne engine is an alpha or gamma type Stirling engine with one or more liquid pistons. It contains a working gas, and either two liquid pistons or one liquid piston and a displacer.

W

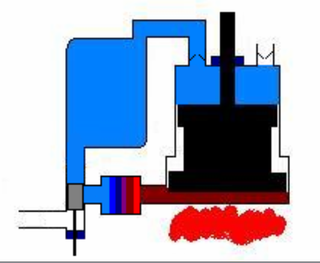

WA free-piston engine is a linear, 'crankless' internal combustion engine, in which the piston motion is not controlled by a crankshaft but determined by the interaction of forces from the combustion chamber gases, a rebound device and a load device.

W

WAn indicator diagram is a chart used to measure the thermal, or cylinder, performance of reciprocating steam and internal combustion engines and compressors. An indicator chart records the pressure in the cylinder versus the volume swept by the piston, throughout the two or four strokes of the piston which constitute the engine, or compressor, cycle. The indicator diagram is used to calculate the work done and the power produced in an engine cylinder or used in a compressor cylinder.

W

WAn internal combustion engine (ICE) is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is applied typically to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into useful kinetic energy and is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where weight or size of the engine is important.

W

WThe intake/inlet over exhaust, or "IOE" engine, known in the US as F-head, is a four-stroke internal combustion engine whose valvetrain comprises OHV inlet valves within the cylinder head and exhaust side-valves within the engine block.

W

WThe Jeep Tornado engine was the first post-World War II U.S.-designed mass-produced overhead cam (OHC) automobile engine. The 230.5 cu in (3.78 L) straight-six was introduced in mid-year 1962, and replaced the flathead 6-226 Willys Super Hurricane that was in use since 1954.

W

WIn a reciprocating piston engine, the stroke ratio, defined by either bore/stroke ratio or stroke/bore ratio, is a term to describe the ratio between cylinder bore diameter and piston stroke length. This can be used for either an internal combustion engine, where the fuel is burned within the cylinders of the engine, or external combustion engine, such as a steam engine, where the combustion of the fuel takes place outside the working cylinders of the engine.

W

WThe mean piston speed is the average speed of the piston in a reciprocating engine. It is a function of stroke and RPM. There is a factor of 2 in the equation to account for one stroke to occur in 1/2 of a crank revolution and a '60' to convert seconds from minutes in the RPM term.

W

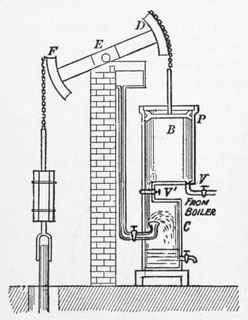

WThe atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

W

WAn Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine. It is the thermodynamic cycle most commonly found in automobile engines.

W

WA pressure–volume diagram is used to describe corresponding changes in volume and pressure in a system. They are commonly used in thermodynamics, cardiovascular physiology, and respiratory physiology.

W

WThe rhombic drive is a specific method of transferring mechanical energy, or work, used when a single cylinder is used for two separately oscillating pistons.

W

WReciprocating engine cylinders are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston.

W

WA steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and flywheel, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

W

WA Stirling engine is a heat engine that is operated by the cyclic compression and expansion of air or other gas at different temperatures, resulting in a net conversion of heat energy to mechanical work. More specifically, the Stirling engine is a closed-cycle regenerative heat engine with a permanent gaseous working fluid. Closed-cycle, in this context, means a thermodynamic system in which the working fluid is permanently contained within the system, and regenerative describes the use of a specific type of internal heat exchanger and thermal store, known as the regenerator. Strictly speaking, the inclusion of the regenerator is what differentiates a Stirling engine from other closed-cycle hot air engines.

W

WElliott J. Stoddard invented and patented two versions of the Stoddard engine, the first in 1919 and the second in 1933. The general engine classification is an external combustion engine with valves and single-phase gaseous working fluid. The internal working fluid was originally air, although in modern versions, other gases such as helium or hydrogen may be used.

W

WIn a reciprocating piston engine, the stroke ratio, defined by either bore/stroke ratio or stroke/bore ratio, is a term to describe the ratio between cylinder bore diameter and piston stroke length. This can be used for either an internal combustion engine, where the fuel is burned within the cylinders of the engine, or external combustion engine, such as a steam engine, where the combustion of the fuel takes place outside the working cylinders of the engine.

W

WThe sun and planet gear is a method of converting reciprocating motion to rotary motion and was used in the first rotative beam engines.

W

WA T-head engine is an early type of internal combustion engine that became obsolete after World War I. It is a sidevalve engine that is distinguished from the much more common L-head by its placement of the valves. The intake valves are on one side of the engine block and the exhaust valves on the other. Seen from the end of the crankshaft, in cutaway view, the cylinder and combustion chamber resembles a T - hence the name "T-head". An L-head has all valves at the same side.

W

WThe Harwell TMG Stirling engine, an abbreviation for "Thermo-Mechanical Generator", was invented in 1967 by E. H. Cooke-Yarborough at the Harwell Labs of the United Kingdom Atomic Energy Authority. It was intended to be a remote electrical power source with low cost and very long life, albeit by sacrificing some efficiency. The TMG was at one time the only Stirling engine sold by a manufacturer, namely HoMach Systems Ltd., England.

W

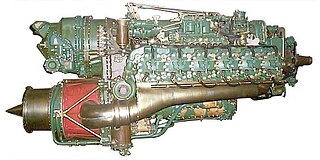

WA turbo-compound engine is a reciprocating engine that employs a turbine to recover energy from the exhaust gases. Instead of using that energy to drive a turbocharger as found in many high-power aircraft engines, the energy is instead sent to the output shaft to increase the total power delivered by the engine. The turbine is usually mechanically connected to the crankshaft, as on the Wright R-3350 Duplex-Cyclone, but electric and hydraulic power recovery systems have been investigated as well.

W

WThe uniflow type of steam engine uses steam that flows in one direction only in each half of the cylinder. Thermal efficiency is increased by having a temperature gradient along the cylinder. Steam always enters at the hot ends of the cylinder and exhausts through ports at the cooler centre. By this means, the relative heating and cooling of the cylinder walls is reduced.

W

WThe Volkswagen-Audi V8 engine family is a series of mechanically similar, gasoline-powered and diesel-powered, V-8, internal combustion piston engines, developed and produced by the Volkswagen Group, in partnership with Audi, since 1988. They have been used in various Volkswagen Group models, and by numerous Volkswagen-owned companies. The first spark-ignition gasoline V8 engine configuration was used in the 1988 Audi V8 model; and the first compression-ignition diesel V8 engine configuration was used in the 1999 Audi A8 3.3 TDI Quattro. V8 gasoline and diesel engine configurations have and variants been used in most Audi, Volkswagen, Porsche, Bentley, and Lamborghini models ever since. The larger-displacement diesel V8 engine configuration has also been used in various Scania commercial vehicles; such as in trucks, buses, and marine applications.

W

WAxial engines are a type of reciprocating engine with pistons arranged around an output shaft with their axes parallel to the shaft. Barrel refers to the cylindrical shape of the cylinder group whilst the Z-crank alludes to the shape of the crankshaft.