W

WA mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals, working animal, wind (windmill) or water (watermill). In modern era, they are usually powered by electricity.

W

WAn animal engine is a machine powered by an animal. Horses, donkeys, oxen, dogs, and humans have all been used in this way. An unusual example of an animal engine was recorded at Portland, Victoria in 1866. A kangaroo had been tamed and trained to work a treadmill which drove various items of machinery.

W

WAn arrastra is a primitive mill for grinding and pulverizing (typically) gold or silver ore. Its simplest form is two or more flat-bottomed drag stones placed in a circular pit paved with flat stones, and connected to a center post by a long arm. With a horse, mule or human providing power at the other end of the arm, the stones were dragged slowly around in a circle, crushing the ore. Some arrastras were powered by a water wheel; a few were powered by steam or gasoline engines, and even electricity.

W

WA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

W

WBark mills, also known as Catskill’s mills, are water, steam, horse, ox or wind-powered edge mills used to process the bark, roots, and branches of various tree species into a fine powder known as tanbark, used for tanning leather. This powdering allowed the tannin to be extracted more efficiently from its woody source material. A barker would strip the bark from trees so that it might be ground in such mills, and the dried bark was often stored in bark houses.

W

WA bone crusher is a device regularly used for crushing animal bones. Bones obtained during slaughter are cleaned, boiled in water and dried for several months. After that, they are suitable for crushing with the special machine into a relatively dry gritty powder which is used as fertilizer.

W

WA burr mill, or burr grinder, is a mill used to grind hard, small food products between two revolving abrasive surfaces separated by a distance usually set by the user. When the two surfaces are set far apart, the resulting ground material is coarser, and when the two surfaces are set closer together, the resulting ground material is finer and smaller. Often, the device includes a revolving screw that pushes the food through. It may be powered electrically or manually.

W

WA cider mill, also known as a cidery, is the location and equipment used to crush apples into apple juice for use in making apple cider, hard cider, applejack, apple wine, pectin and other products derived from apples. More specifically, it refers to a device used to crush or grind apples as part of the overall juice production.

W

WCollis Mill is a Grade II* listed smock mill at Great Thurlow, Suffolk, England which has been restored.

An edge mill is a mill used for crushing or grinding in which stones roll around on their edges on a level circular bed. They were developed in China in the third century and are still used today in remote villages around the world. When the millstones were replaced with iron or steel disks in the 19th century, the mills were known as Chilean mills.

W

WA field mill, also known as a camp mill, was a premodern vehicle which acted as a mobile mill used for grinding grains, which had the very practical use of feeding a moving army.

W

WA gristmill grinds cereal grain into flour and middlings. The term can refer to either the grinding mechanism or the building that holds it. Grist is grain that has been separated from its chaff in preparation for grinding.

W

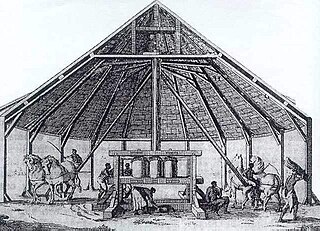

WA horse mill is a mill, sometimes used in conjunction with a watermill or windmill, that uses a horse engine as the power source. Any milling process can be powered in this way, but the most frequent use of animal power in horse mills was for grinding grain and pumping water. Other animal engines for powering mills are powered by dogs, donkeys, oxen or camels. Treadwheels are engines powered by humans.

W

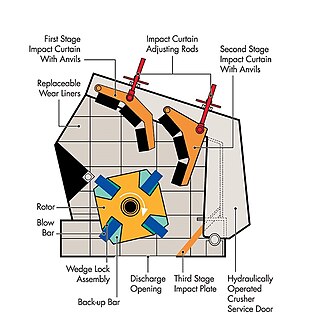

WImpact mills are one of two general classes of milling devices used to reduce the particle size of a material.

W

WA jet mill grinds materials by using a high speed jet of compressed air or inert gas to impact particles into each other. Jet mills can be designed to output particles below a certain size while continuing to mill particles above that size, resulting in a narrow size distribution of the resulting product. Particles leaving the mill can be separated from the gas stream by cyclonic separation.

W

WLa Cueva Historic District, in Mora County, New Mexico near Mora, New Mexico, is a historic district which was listed on the National Register of Historic Places in 1973. The listing included five contributing buildings on 47 acres (19 ha).

W

WThe MIAG Mühlenbau und Industrie Aktiengesellschaft was a mechanical engineering company from Braunschweig, Germany which was acquired by Bühler in Uzwil, Switzerland in 1972.

W

WA miller is a person who operates a mill, a machine to grind a grain to make flour. Milling is among the oldest of human occupations. "Miller", "Milne", and other variants are common surnames, as are their equivalents in other languages around the world. Milling existed in hunter-gatherer communities, and later millers were important to the development of agriculture.

W

WA millrind or simply rind is an iron support, usually four-armed or cross-shaped, for the upper ("runner") stone in a pair of millstones.

W

WMillstones or mill stones are stones used in gristmills, for grinding wheat or other grains. They are sometimes referred to as grindstones or grinding stones.

W

WThe Mühlsteinbrüche south of Jonsdorf in the Zittau Mountains in Saxony are a region of bizarre rock formations, which have been formed by the quarrying of sandstone for millstones and also by weathering processes. They are a popular hiking and climbing area. An educational trail runs through the region which has an area of about 35 hectares.

W

WAn oil mill is a grinding mill designed to crush or bruise oil-bearing seeds, such as linseed or peanuts, or other oil-rich vegetable material, such as olives or the fruit of the oil palm, which can then be pressed to extract vegetable oils, which may used as foods or for cooking, as oleochemical feedstocks, as lubricants, or as biofuels. The pomace or press cake – the remaining solid material from which the oil has been extracted – may also be used as a food or fertilizer.

W

WA powder mill was a mill where gunpowder is made from sulfur, saltpeter and charcoal. Crude grinding and mixing operations like the Frankford Powder-Mill of Philadelphia were a cottage industry until the industrial revolution brought improved product quality through the following procedures:

W

WQuern-stones are stone tools for hand-grinding a wide variety of materials. They are used in pairs. The lower stationary stone of early examples is called a saddle quern, while the upper mobile stone is called a muller, rubber or handstone. The upper stone was moved in a back-and-forth motion across the saddle quern. Later querns are known as rotary querns. The central hole of a rotary quern is called the eye, and a dish in the upper surface is known as the hopper. A handle slot contained a handle which enabled the rotary quern to be rotated. They were first used in the Neolithic era to grind cereals into flour.

W

WRoller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills. Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling.

W

WThe Santa Olaja mill is located in the Joyel Marshes in Soano, in the municipality of Arnuero in the autonomous community of Cantabria, Spain. It was declared a Bien de Interés Cultural in November 2013.

W

WThe Scherpenberg mill, located in Westmalle, Belgium, is a tower mill that was built in 1843 to grind grain into flour. It is currently owned and operated by the municipal authorities of Malle, the only hours of operation being Sunday from 1:30 P.M. until 5:00 P.M.

W

WA stamp mill is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a type of unit operation.

W

WA steam mill is a type of grinding mill using a stationary steam engine to power its mechanism.

W

WSuvača in Kikinda, Serbia, is one of the three remaining horse-powered dry mills in the whole of Europe.

W

WA tide mill is a water mill driven by tidal rise and fall. A dam with a sluice is created across a suitable tidal inlet, or a section of river estuary is made into a reservoir. As the tide comes in, it enters the mill pond through a one-way gate, and this gate closes automatically when the tide begins to fall. When the tide is low enough, the stored water can be released to turn a water wheel.

W

WA trapiche is a mill made of wooden rollers used to extract juice from fruit, originally olives, and since the Middle Ages, sugar cane as well. By extension the word is also sometimes applied to the location of the mill, whether the workshop or the entire plantation.

W

WA treadwheel, or treadmill, is a form of engine typically powered by humans. It may resemble a water wheel in appearance, and can be worked either by a human treading paddles set into its circumference (treadmill), or by a human or animal standing inside it (treadwheel). These devices are no longer used for power or punishment, and the term "treadmill" has come to mean an exercise machine for running or walking in place.

W

WThe Turley Mill and Distillery Site is a historic site on the Rio Hondo about 11 miles (18 km) north of Taos, New Mexico. It was a mill and distillery which served as the headquarters of Simeon Turley's commercial and manufacturing empire. Simeon Turley (1809-1847) and his brothers Stephen Turley (1786-1851) and Jesse B. Turley (1801-1861) transported goods from Franklin, Missouri to Taos via wagon train on the Santa Fe Trail. About 1827-1829 Simeon settled in Arroyo Hondo and established the mill and distillery as a popular trading post and "watering hole." Simeon was murdered in the Taos Revolt of January 1847 and the mill and distillery site was all but destroyed. Simeon Turley is buried in the Kit Carson Memorial Cemetery in Taos. The mill and distillery site was listed on the State of New Mexico Register of Cultural Properties in 1969 and on the National Register of Historic Places in 1978.

W

WFor centuries, the watermills on the Zala river had co-existed in a single harmonious unity with each other as well as with the river, the Zala valley and Zala meadow, both latter ones renowned for their beauty. Landscape rehabilitation would indeed be necessary because due to the closure of the mills and the destruction of the sluices, the level of the ground water in the meadows, usually having very loamy soil, has dramatically decreased, which has had detrimental impacts on the condition of the meadows. The declining tendency in the grassland culture hasn't helped either. What is more, in several cases parts of the meadows were turned into arable lands or industrial sites. The final blow to the deteriorating meadows that gradually grew characterless was dealt by the disgraceful regulation of the river Zala in the beginning of the 1960s. A further station of the process was the elimination of the mills from the life of the river for all. „There were about 200 known steam mills and watermills in the county Zala at the end of the 1800s (Molnár 2015). According to the statistical data of the Zala county archives of the year 1949, there were about 180 mills in operation in the county then. In the beginning of the 1940s, there were still about 37 mills grinding on the river Zala. One can still find water in some old mill-ponds. For the history of a miller's family see Jakosa 2011, 2012, both in Hungarian). These ponds provide suitable habitat for some aquatic organisms. As for the history of the published data and photos, I. Hajdu, J. Izsák, Á. Jakosa, Gy. Kummer and Mrs. M. Marx, the latter working with Göcseji Muzeum, Zalaegerszeg decided in 2004 to start gathering documents and data systematically on the watermills along the river Zala. We have based our selection of the mills to be presented on a list from the year 1949 preserved in the Zala-county archives. The chart was provided by Mr. Gy. Kummer. A significant number of the photos were also taken by him. The mills indicated by red characters exist today mainly in documents and in the mind's eye only. For the possibility of hydropower by the water of small rivers, e.g. Zala, see Gerse 2014.