W

WAn abrasive saw, also known as a cut-off saw or chop saw, is a circular saw which is typically used to cut hard materials, such as metals, tile, and concrete. The cutting action is performed by an abrasive disc, similar to a thin grinding wheel. Technically speaking this is not a saw, as it does not use regularly shaped edges (teeth) for cutting.

W

WA bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

W

WA circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

W

WA cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade, allowing both the blade and material being cut to remain cool. This is in contrast to an abrasive saw, which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

W

WA wire saw is a saw that uses a metal wire or cable for cutting. Industrial wire saws are usually powered. There are also hand-powered survivalist wire saws suitable for cutting branches. Wire saws are classified as continuous or oscillating. Sometimes the wire itself is referred to as a "blade".

W

WA firewood processor is a machine designed to cut and split firewood with minimal manual handling of the logs. There are typically four main parts of the machine, each dedicated to a separate function. Processing begins with a log pile – a pile of logs that have been de-limbed and cut to an appropriate length, generally 10–12 feet (3.0–3.7 m). Popular brands include Multitek, Wood Beaver, DYNA, Hakki Pilke, and Blockbuster. Many individuals use processors commercially and also privately as a hobby. Others choose to rent them as an alternative to purchasing.

W

WA hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw.

W

WLaser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC are used to direct the material or the laser beam generated. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

W

WA log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Many log splitters consist of a hydraulic or electrical rod and piston assembly and these are often rated by the tons of force they can generate. The higher the force rating, the greater the thickness or length of the rounds that can be split. The log splitter consists of all four major hydraulic components.

W

WA pendulum saw or swing saw is a mechanically powered circular saw with the blade mounted so it can swing into the material.

W

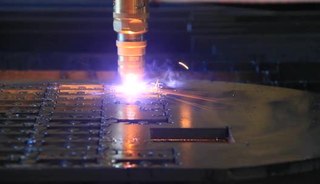

WPlasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops.

W

WA plunge saw or plunge-cut saw is a type of hand-held circular saw which differs from a regular circular saw in that it can plunge into the material to a predetermined depth during the cut. In other words, the depth-of-cut is not fixed and often can be adjusted to be just slightly over the thickness of the board being cut. This property also allows a plunge saw to cut shallow grooves into the workpiece, if necessary. Compared to traditional hand-held circular saws, plunge saws are said to increase operator safety, as well as allowing for reduced splintering and tear-out.

W

WA punch press is a type of machine press used to cut holes in material. It can be small and manually operated and hold one simple die set, or be very large, CNC operated, with a multi-station turret and hold a much larger and complex die set.

W

WRoll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

W

WA pendulum saw or swing saw is a mechanically powered circular saw with the blade mounted so it can swing into the material.

W

WA water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal, stone or glass, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

W

WA wire saw is a saw that uses a metal wire or cable for cutting. Industrial wire saws are usually powered. There are also hand-powered survivalist wire saws suitable for cutting branches. Wire saws are classified as continuous or oscillating. Sometimes the wire itself is referred to as a "blade".