W

WAn automatic center punch is a hand tool used to produce a dimple in a workpiece. It performs the same function as an ordinary center punch but without the need for a hammer. When pressed against the workpiece, it stores energy in a spring, eventually releasing it as an impulse that drives the punch, producing the dimple. The impulse provided to the point of the punch is quite repeatable, allowing for uniform impressions to be made.

W

WA ball-peen or ball pein hammer, also known as a machinist's hammer, is a type of peening hammer used in metalworking. It has two heads, one flat and the other, called the peen, rounded. It is distinguished from a cross-peen hammer, diagonal-peen hammer, point-peen hammer, or chisel-peen hammer by having a hemispherical peen.

W

WA C-clamp or G-clamp or G-cramp is a type of clamp device typically used to hold a wood or metal work piece, and often used in, but are not limited to, carpentry and welding. Often believed that these clamps are called "C" clamps because of their C-shaped frame, or also often called C-clamps or G-clamps because including the screw part, they are shaped like an uppercase letter G. However, in fact, they were originally called a carriage maker's clamp, or Carriage Clamp.

W

WDie grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material. All such tools are conceptually similar, with no bright dividing line between die grinders and rotary tools, although the die grinder name tends to be used for pneumatically driven heavy-duty versions whereas the rotary tool name tends to be used for electric lighter-duty versions. Flexible shaft drive versions also exist. The die grinder name comes from one of their earliest and archetypal applications, tool and die work, where they were used to create the precise contours of dies or molds. Especially before the advent of widespread CNC usage, they were heavily relied upon for contouring via manual skill comparable to a sculptor's. CNC now provides much of the contouring for die and mold interior surfaces, but die grinders are still very useful for hundreds of cutting needs, from sculpture-like contouring in the absence of CNC, to cut-off of bar stock, to any of the cutting and grinding needs of fabrication, such as in the work of welders, boilermakers, millwrights, ironworkers, sheet metal workers, to woodworking, hacking, and other hobby or business pursuits. Die grinders are often used for engraving, cylinder head porting, and general shaping of a part.

W

WIn metalworking, a drift pin, drift pin punch, simply drift, is the name for a tool used for localizing a hammer blow. The tool is also used where we want the surrounding surfaces or areas to be protected from hammering. A drift pin is not used as a punch in the traditional sense of the term. Drifts are constructed with wood, light alloys, copper and even of steel. These are usually rods cut to size as for the job. Drifts can be used to remove dents from inaccessible places, for striking pins and keys out. A drift pin is constructed as a tapered rod, with the hammer acting on the large end of the taper. The tapered end of a drift pin is placed into the semi-aligned bolt holes of two separate components, and then driven into the hole. As it is driven in, the taper forces the two components into alignment, allowing for easy insertion of the fastener. Unlike most punches, force should never be applied to the tip of drift pin.

W

WAn F-clamp, also known as a bar clamp or speed clamp, is a type of clamp. The name comes from its "F" shape. The F-clamp is similar to a C-clamp in use, but has a wider opening capacity (throat). This tool is used in woodworking while more permanent attachment is being made with screws or glue, or in metalworking to hold pieces together for welding or bolting.

W

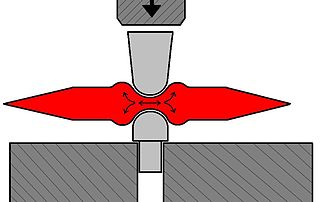

WIn metalworking, a fuller is a tool used to form metal when hot. The fuller has a rounded, either cylindrical or parabolic, nose, and may either have a handle or a shank. The shank of the lower fuller allows the fuller to be inserted into the hardy hole of the anvil. Upper fullers furthermore come in "straight" or "cross" varieties, depending on the orientation of the handle relative to the face.

W

WA hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw.

W

WA hand scraper is a single-edged tool used to scrape metal from a surface. This may be required where a surface needs to be trued, corrected for fit to a mating part, needs to retain oil, or to give a decorative finish.

W

WHardy tools, also known as anvil tools or bottom tools, are metalworking tools used in anvils. A hardy has a square shank, which prevents it from rotating when placed in the anvil's hardy hole. The term "hardy", used alone, refers to a hot cutting chisel used in the square hole of the anvil. Other bottom tools are identified by function. Typical hardy tools include chisels and bending drifts. They are generally used with a matching top tool.

W

WA honing steel, sometimes referred to as sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to re-align blade edges. They are flat, oval, or round in cross-section and up to 1 foot (30 cm) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles.

W

WA knockout punch, also known as a chassis punch, panel punch, Greenlee punch, or a Q-max, is a hand tool used to punch a hole through sheet metal. It is a very simple tool that consists of a punch, die, and screw. There are three different drive systems: manual, ratchet, and hydraulic.

W

WA machinist square or engineer's square is the metalworkers' equivalent of a try square. It consists of a steel blade inserted and either welded or pinned into a heavier body at an angle of 90°. Usually a small notch is present at the inside corner of the square. This prevents small particles from accumulating at the juncture and affecting the square's reading.

W

WA magnetic switchable device is a magnetic fixture that uses one or more permanent magnets in a configuration that allows the external field to be turned on or off. They are used in many applications including optics, metalworking, lifting, and robotics, to attach items to metal surfaces in a secure but temporary way.

W

WA miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

W

WA needlegun scaler, needle scaler or needle-gun is a tool used to remove rust, mill scale, and old paint from metal surfaces. The tool is used in metalwork applications as diverse as home repair, automotive repair and shipboard preservation.

W

WA piercing saw, also known as a jeweler's saw, is a type of saw commonly used in jewelry making on sheet metal. It is usually used on softer metals as the saw is delicate.

W

WPliers are a hand tool used to hold objects firmly, possibly developed from tongs used to handle hot metal in Bronze Age Europe. They are also useful for bending and compressing a wide range of materials. Generally, pliers consist of a pair of metal first-class levers joined at a fulcrum positioned closer to one end of the levers, creating short jaws on one side of the fulcrum, and longer handles on the other side. This arrangement creates a mechanical advantage, allowing the force of the hand's grip to be amplified and focused on an object with precision. The jaws can also be used to manipulate objects too small or unwieldy to be manipulated with the fingers.

W

WA profile gauge or contour gauge is a tool for recording the cross-sectional shape of a surface. Contour gauges consist of a set of steel or plastic pins that are set tightly against one another in a frame which keeps them in the same plane and parallel while allowing them to move independently, perpendicularly to the frame. When pressed against an object, the pins conform to the object. The gauge can then be used to draw the profile or to copy it on to another surface.

W

WA punch is a hard metal rod with a narrow tip at one end and a broad flat "butt" at the other. When used, the narrower end is pointed against a target surface and the broad end is then struck with a hammer or mallet, causing the blunt force of the blow to be transmitted down the rod body and focused more sharply onto a small area. Typically, woodworkers use a ball-peen hammer to strike a punch.

W

WA screw extractor is a tool for removing broken or seized screws. There are two types: one has a spiral flute structure, commonly called an easy out after the trademarked name EZ-Out; the other has a straight flute structure. Screw extractors are intentionally made of hard, brittle steel, and, if too much torque is applied, can break off inside the screw that is being removed. Since the extractor is an extremely hard material, and a typical home shop drill bit will not be able to drill into it, a larger element of difficulty is added to the original screw extraction project. One way to avoid this added difficulty is to drill a hole completely through the screw. Thus, if the fastener breaks, a punch can be used to drive out the easy out from the screw, via the back, or end, of the fastener.

W

WA scriber is a hand tool used in metal work to mark lines on workpieces, prior to machining. The process of using a scriber is called scribing and is just part of the process of marking out. It is used instead of pencils or ink lines, because the latter are hard to see, easily erased, and imprecise due to their wide mark; scribe lines are thin and semi-permanent. On non-coated workpieces marking blue is commonly used to increase the contrast of the mark lines.

W

WA tap wrench is a hand tool used to turn taps or other small tools, such as hand reamers and screw extractors.

W

WA thread restorer is a tool used to fix threads on nuts or bolts that have become damaged.

W

WTongs are a type of tool used to grip and lift objects instead of holding them directly with hands. There are many forms of tongs adapted to their specific use. Some are merely large pincers or nippers, but most fall into these few classes:Tongs that have long arms terminating in small flat circular ends of tongs and are pivoted at a joint close to the handle used to handle delicate objects. Common fire-tongs, used for picking up pieces of coal and placing them on a fire without burning fingers or getting them dirty are of this type. Tongs for grilling, tongs for serving salad or spaghetti are kitchen utensil of the same type. They provide a way to move, rotate and turn the food with delicate precision, or fetch a full serving in one grab. Tongs consisting of a single band of bent metal, as in sugar tongs, most asparagus tongs and the like. Sugar tongs are usually silver, with claw-shaped or spoon-shaped ends for serving lump sugar. Asparagus tongs are usually similar but larger, with a band near the head that limits how far the tongs can expand. Asparagus tongs for serving were introduced in 18th-century England, with smaller versions for eating asparagus appearing in the 19th century. Tongs in which the pivot or joint is placed close to the gripping ends are used to handle hard and heavy objects. Driller's round tongs, blacksmith's tongs or crucible tongs are of this type.

W

WA vise or vice is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

W

WA wire brush is a tool consisting of a brush whose bristles are made of wire, most often steel wire. The steel used is generally a medium- to high-carbon variety and very hard and springy. Other wire brushes feature bristles made from brass or stainless steel, depending on application. Wires in a wire brush can be held together by epoxy, staples, or other binding. Wire brushes usually either have a handle of wood or plastic or are formed into a wheel for use on angle grinders, bench grinders, pistol-grip drill motors, or other power tools.

W

WA workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes:A comfortable height for working with provisions for seated or standing work A way to fix the workpiece to the surface so that it may be worked with both hands Provisions for mounting, storing and accessing tools

W

WA wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.