W

WPackaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, palletizing.

W

WA barcode printer is a computer peripheral for printing barcode labels or tags that can be attached to, or printed directly on, physical objects. Barcode printers are commonly used to label cartons before shipment, or to label retail items with UPCs or EANs.

W

WA barcode reader is an optical scanner that can read printed barcodes, decode the data contained in the barcode and send the data to a computer. Like a flatbed scanner, it consists of a light source, a lens and a light sensor translating for optical impulses into electrical signals. Additionally, nearly all barcode readers contain decoder circuitry that can analyze the barcode's image data provided by the sensor and sending the barcode's content to the scanner's output port.

W

WBottling lines are production lines that fill a product, generally a beverage, into bottles on a large scale. Many prepared foods are also bottled, such as sauces, syrups, marinades, oils and vinegars.

W

WA can seamer is a machine used to seal the lid to the can body. The lid or "end" is usually tinplated steel (food) or aluminum (drinks) while the body can be of metal, paperboard or plastic.

W

WA cartoning machine or cartoner, is a packaging machine that forms cartons: erect, close, folded, side seamed and sealed cartons.

W

WA case sealer or box sealer is a piece of equipment used for closing or sealing corrugated boxes. It is most commonly used for regular slotted containers (RSC) and can involve adhesive, box sealing tape, or Gummed tape.

W

WA checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

W

WA conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

W

WDrum pump, barrel pump, and transfer pump refer to pumps that are used to empty barrels, tanks, IBCs and drums. Many liquids used on manufacturing and processing plants are delivered in 100 or 200 litre barrels and are too heavy to tip to empty the liquids inside. Drum pumps range from simple siphon based devices to sophisticated highly-engineered machinery.

W

WA heat gun is a device used to emit a stream of hot air, usually at temperatures between 100 °C and 550 °C (200-1000 °F), with some hotter models running around 760 °C (1400 °F), which can be held by hand. Heat guns usually have the form of an elongated body pointing at what is to be heated, with a handle fixed to it at right angles and a trigger, in the same general layout as a handgun, hence the name. A lighter duty heat gun is similar to a portable Hair dryer.

W

WA heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic monolayers or with materials having several layers, at least one being thermoplastic. Heat sealing can join two similar materials together or can join dissimilar materials, one of which has a thermoplastic layer.

W

WInduction sealing is the process of bonding thermoplastic materials by induction heating. This involves controlled heating an electrically conducting object by electromagnetic induction, through heat generated in the object by eddy currents.

W

WAn industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

W

WAn injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit.

W

WITW Mima Packaging Systems is the European marketing division of ITW's Specialty Systems businesses, manufacturing fully automatic stretch wrapping machines in Finland, semi-automatic and automatic machines in Bulgaria and manufacturing film in Belgium and Ireland.

W

WLabel dispensers and label applicators are machines built to simplify the process of removing a label from its liner or backing tape. Some are bench-top for dispensing the labels while others include the application of the label to the item.

W

WA label printer is a computer printer that prints on self-adhesive label material and/or card-stock (tags). A label printer with built-in keyboard and display for stand-alone use is often called a label maker. Label printers are different from ordinary printers because they need to have special feed mechanisms to handle rolled stock, or tear sheet (fanfold) stock. Common connectivity for label printers include RS-232 serial, Universal Serial Bus (USB), parallel, Ethernet and various kinds of wireless. Label printers have a wide variety of applications, including supply chain management, retail price marking, packaging labels, blood and laboratory specimen marking, and fixed assets management.

W

WA label printer applicator is a basic robot that can automatically print and apply pressure-sensitive labels to various products. Some types of labeling include shipping labeling, content labeling, graphic images, and labeling to comply with specific standards such as those of GS1 and Universal Product Code U.P.C. A pressure-sensitive label consists of a label substrate and adhesive.

W

WLogistics automation is the application of computer software or automated machinery to improve the efficiency of logistics operations. Typically this refers to operations within a warehouse or distribution center, with broader tasks undertaken by supply chain engineering systems and enterprise resource planning systems.

W

WMechanical brake stretch wrappers are manual stretch wrapping systems which consist of a simple structure supporting a roll of film to be stretched and a mechanical brake which acts on the film roll, creating resistance to turning and stretching the film as it is fed out.

W

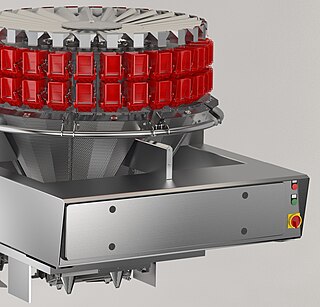

WA multihead weigher is a fast, accurate and reliable weighing machine, used in packing both food and non-food products.

W

WAn orbital stretch wrapper is a means of applying stretchable plastic film to a load, consisting of a roll of stretch wrap supported on a vertical rotating ring and a means of passing a load through the ring's eye horizontally. Several designs are available.

W

WA palletizer or palletiser is a machine which provides automatic means for stacking cases of goods or products onto a pallet.

W

WPlastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1.

W

WSeed counting machines count seeds for research and packaging purposes. The machines typically provide total counts of seeds, or batch sizes for packaging.

W

WA shrink tunnel or heat tunnel is a heated tunnel mounted over or around a conveyor system. Items have shrink film loosely applied; with heat, the film shrinks to fit snugly around the wrapped object.

W

WA staple gun or powered stapler is a hand-held machine used to drive heavy metal staples into wood, plastic, or masonry. Staple guns are used for many different applications and to affix a variety of materials, including insulation, house wrap, roofing, wiring, carpeting, upholstery, and hobby and craft materials. These devices are also known as trigger tackers.

W

WA stapler is a mechanical device that joins pages of paper or similar material by driving a thin metal staple through the sheets and folding the ends. Staplers are widely used in government, business, offices, work places, homes and schools.

W

WA tape dispenser is an object that holds a roll of tape and has a mechanism at one end to shear the tape. Dispensers vary widely based on the tape they dispense. Abundant and most common, clear tape dispensers are commonly made of plastic, and may be disposable. Other dispensers are stationary and may have sophisticated features to control tape usage and improve ergonomics.

W

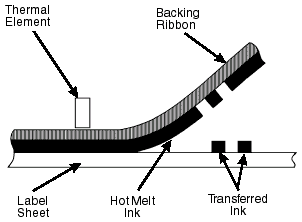

WThermal-transfer printing is a digital printing method in which material is applied to paper by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with direct thermal printing, where no ribbon is present in the process.

W

WTurntable stretch wrappers are a type of automatic and semi-automatic stretch wrapping system. A load is placed on a turntable, which rotates relative to the film roll, which is housed in a carriage attached to a vertical "mast" on which it may move up and down. In the simplest turntable systems, stretch is achieved by rotating the load at a speed in which the take-up demand on the load surface is faster than the rate at which the film is allowed to be fed, being limited by a brake system.

W

WUltrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials.

W

WA vertical form fill sealing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for food, and a wide variety of other products. Walter Zwoyer, the inventor of the technology, patented his idea for the VFFS machine in 1936 while working with the Henry Heide Candy Company. The machine constructs plastic bags and stand-up pouches out of a flat roll of film, while simultaneously filling the bags with product and sealing the filled bags. Both solids and liquids can be bagged using this packaging system.

W

WWashdown is the process of cleaning or washing a surface for appearance, sanitation, or removal of contamination. It may involve pressure washing. Sometimes wash down involves rinsing with fresh water; other times it involves use of detergents and other chemicals.

W

WThe workerbot is a trademark, which was developed by the pi4_robotics GmbH to describe an industrial robot, which was modeled with its possibilities of movement and its sensory abilities of a human.